Cold Chain Solutions

Improve performance, reduce costs + get real-time optimisation capabilities.

We can rapidly create a custom Cold Chain solution that delivers real-time visibility, performance and bottom-line improvements, fast + affordably.

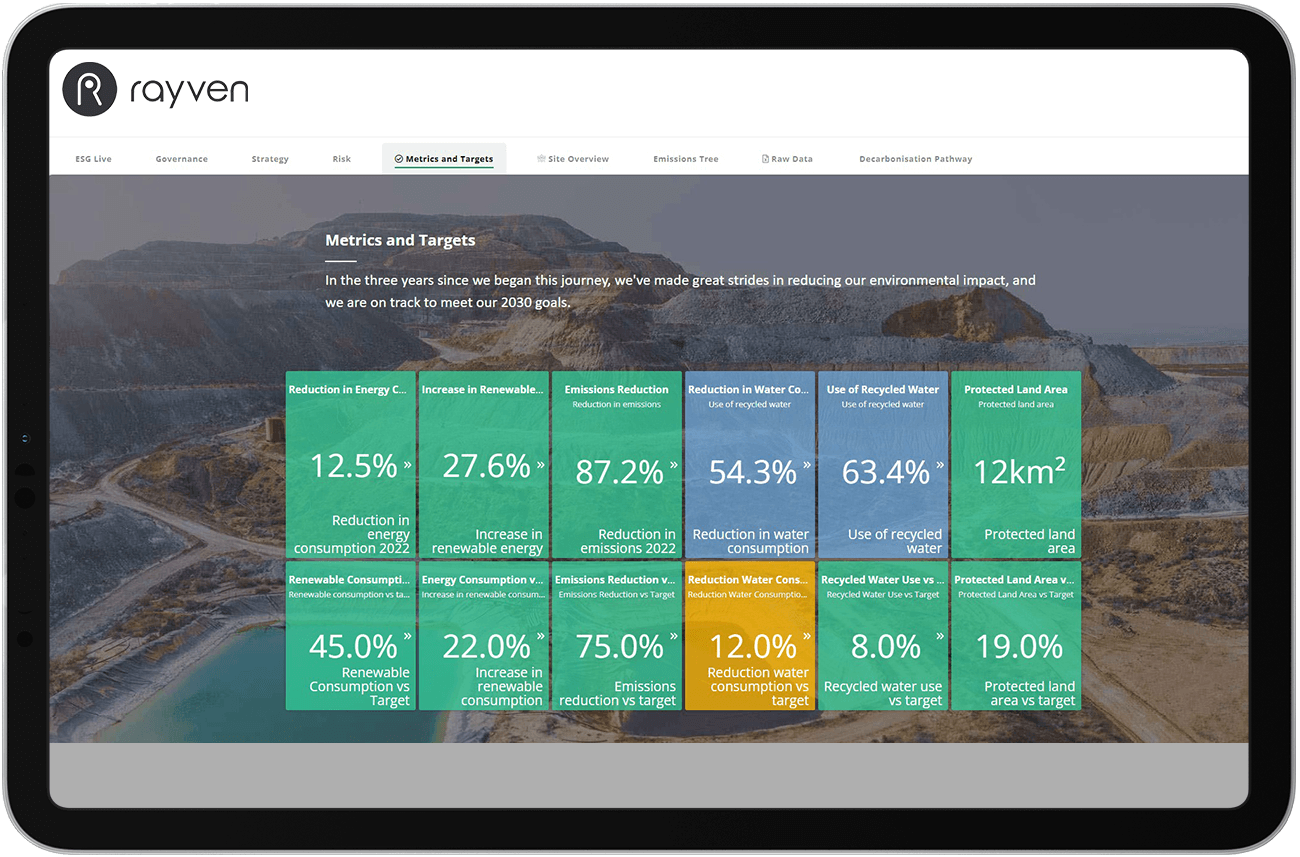

Add real-time transparency, lower running costs + report on compliance, simply.

Cold Chains are sensitive, geographically dispersed, and come with their own set of highly-challenging compliance and reporting challenges.

Using our Rayven Platform and proven solution templates; we integrate infield devices, third-party systems + assets to deliver real-time and predictive insights on performance and to improve it.

With universal integration, machine learning, automation + AI built-in; a Rayven solution helps you to monitor + maintain performance, simply.

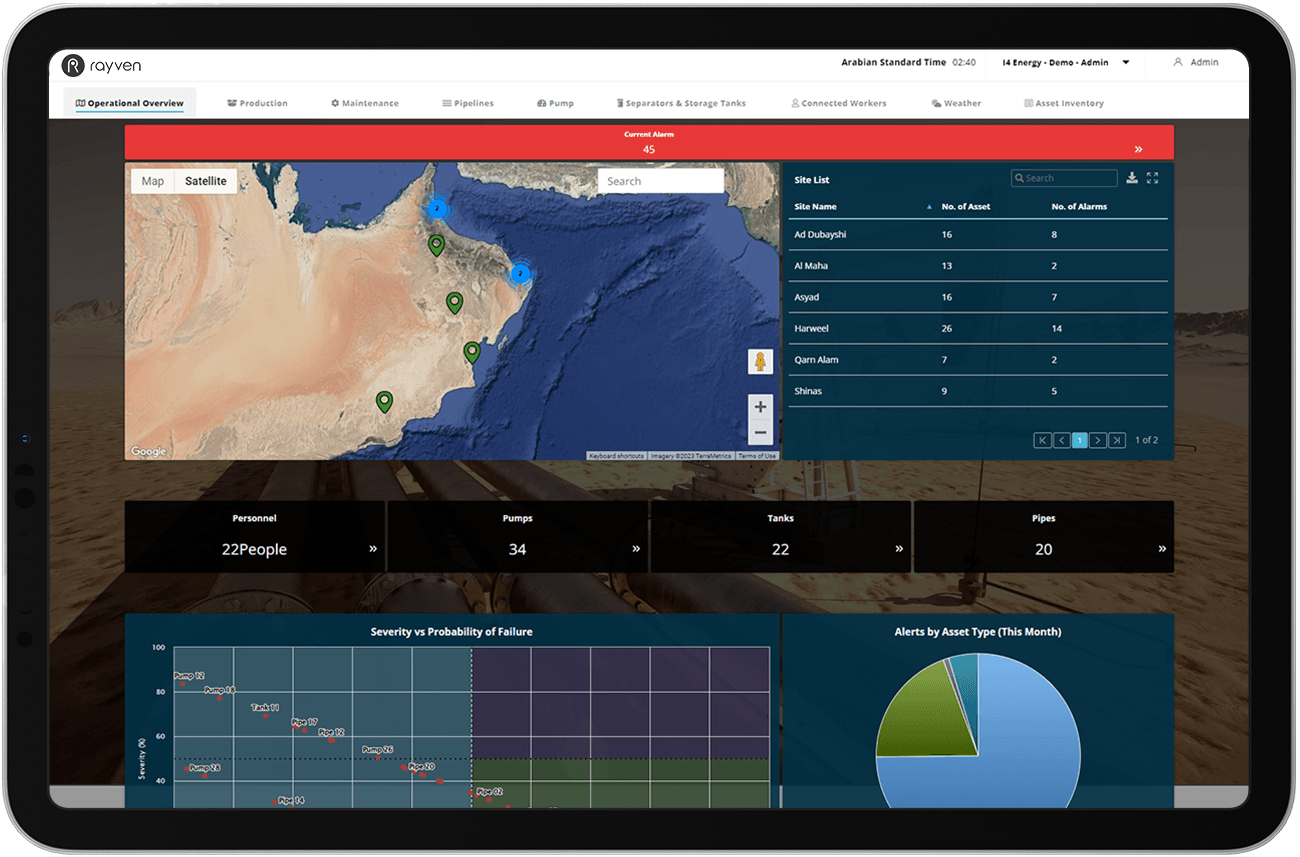

Remote, real-time refrigeration monitoring + management

Monitor and manage your geographically dispersed cold chain assets and fleets in real-time, simply, all from a single solution. Examine efficiency and compare performance.

Find optimal configurations + reduce energy costs

Run your cold chain assets at optimal configurations at all times using inbuilt machine learning. Understand best practices and get insights that aid decision-making.

Set thresholds + trigger temperature alerts

Set-up performance thresholds and trigger instant alerts to employees nearby. Use automation + control to prevent compliance breaches without the need for human intervention.

Predict maintenance, prevent failures + extend lifespan

Continuously monitor your assets' performance to predict failures and schedule maintenance. Keep assets running for longer, reduce unplanned maintenance, and prevent breakdowns.

Fast-to-deploy,

infinitely scalable

Deploy our cold chain solution at a single facility or select assets, add more over time and build-in automation, machine learning + AI capabilities.

Fits all your existing

hardware + technologies

Our cold chain solution can integrate with any machinery, system, hardware, sensor, technology, or data repository - you don't need to buy new assets.

Low cost at

any scale

Rayven's cold chain solution can be tailored to fit your needs and we charge you only for what you use - it's the only Industry 4.0 platform you’ll ever need.

End-to-end services

+ 24/7 support

We'll help with data science, machine learning, solution design, build, deployment, scaling, technical support, and more.

How Rayven works with you to deliver, fast.

How Rayven creates your solution in weeks:

After onboarding and a thorough discovery process with you and your team, we'll utilise our tried and tested solution delivery model.

1: We connect to what you already use

Asset systems, site tools, safety platforms, plant data, sensors, project tools, files - whatever you use - united. No rip-and-replace.

2: We make your operational data usable

All your data is cleaned, stored + made available within Rayven, so that all your teams and systems have access to it.

3: We build the logic, dashboards + alerts

We create the things you'll need, from custom UIs and reports, through to the logic, AI and automations that deliver it.

4: We run it, add capabilities/AI + scale

We don't just deliver it and forget; we'll support your use with 24/7 support, updates + work with you to develop your solution.

Your Cold Chain solution will integrate with anything.

See Rayven in-action:

Book a 1-on-1 demo with one of our Australia-based experts, tailored to your needs.

Discover some of Rayven's Cold Chain Monitoring solutions' real-world use cases.

Cold Storage Monitoring, Compliance + Energy Efficiency.

Discover how our IoT solution enabled our customer to better monitor their cold storage environment, ensuring that their products are stored at the correct temperatures and reduce energy usage. Read More.

Industrial HVAC Predictive Maintenance + Energy Efficiency.

Industrial HVAC consumes large amounts of energy and requires continuous management oversight - our IoT solution makes this easy and enables you to save time and money in the process. Read More.

Greenhouse Management, Monitoring + Yield Optimisation.

The rapid growth in demand for fresh fruit and vegetables year-round has also placed pressure on delivery, costs and product quality - something AI + IoT technology can make easy. Read More.

Why Rayven costs less than enterprise solutions.

Mid-market operations need serious systems, but not the cost and chaos that come with traditional enterprise software.

Rayven delivers the same outcomes with a radically lighter footprint + much, much faster.

Everything you need in one platform.

Data, apps, automation + everything to run them. One license.

We own, build + run our own technology.

No resellers or third-party mark-ups; new capabilities are aligned to industry.

Delivered for you by our specialists.

We design, build, deploy + support - you don’t need internal developers.

Small-footprint deployments that scale.

We can start small, expand across sites + teams without engineering or lock-in.