Quarry Monitoring Solution

Increase yields, deliver real-time transparency + improve ESG, simply.

We rapidly create and deliver custom Quarry Monitoring solutions that will fit your site, current assets + objectives, fast + affordably.

Establish real-time operational and strategic metrics, lower running costs + increase output with a custom, real-time solution.

Quarrying comes with multiple and unique HSEC, production + compliance challenges that real-time technology can help with.

Using our Rayven platform and proven solution templates; we integrate in-field devices, systems + assets to deliver real-time and predictive insights to the people who need them, anywhere.

With universal integration, machine learning, automation + AI built-in; a Rayven solution helps you to improve environmental monitoring, asset performance, predict maintenance needs + much more.

Remote, real-time asset monitoring + management

Monitor and manage your geographically dispersed mining assets and fleets in real-time, simply. Examine yields, quality, emissions, efficiency, and much more. Increase utilisation.

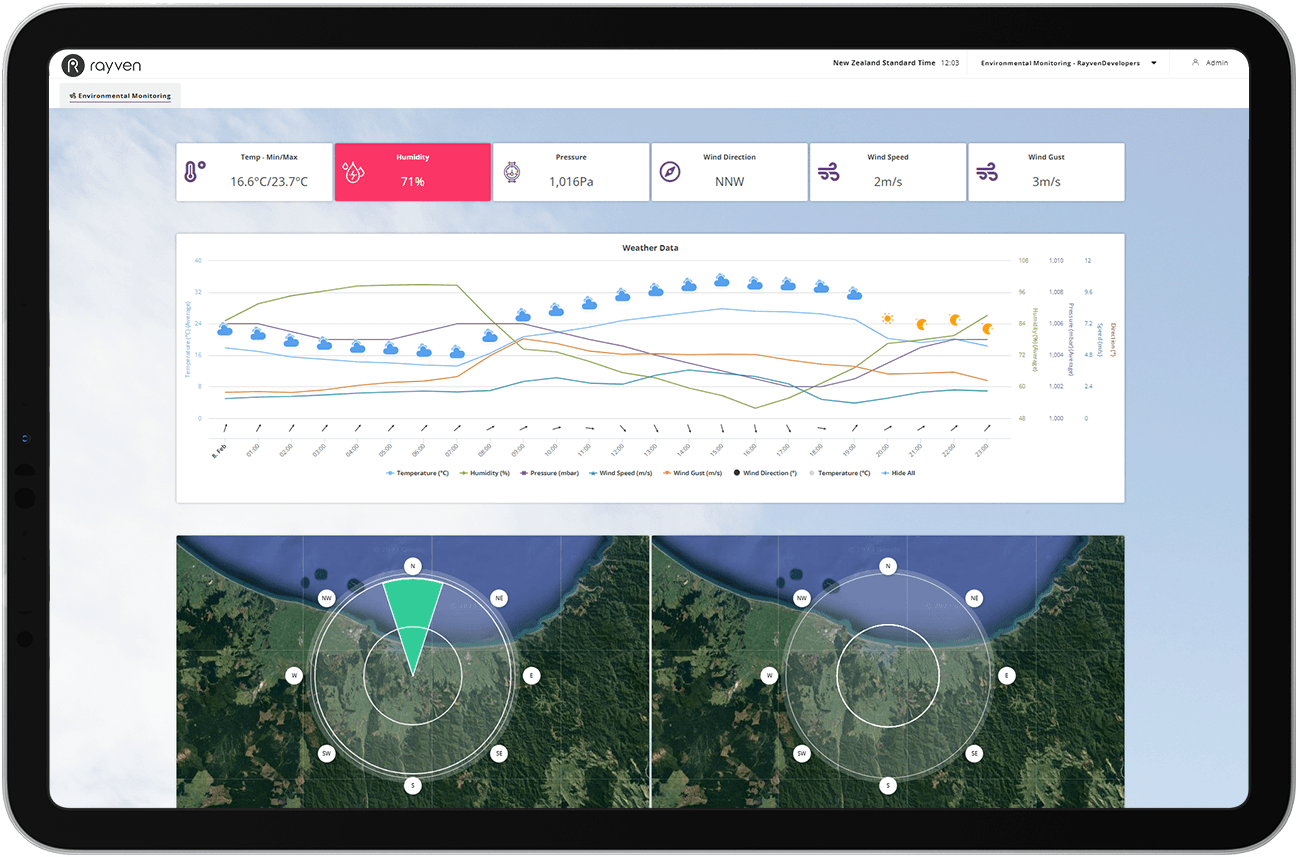

Monitor the surrounding environment

Track all your critical environmental metrics remotely and in real-time, including dust, air quality, noise, light - anything. Integrate weather data and use predictive analytics to plan + optimise future operations.

Set HSEC thresholds, trigger alerts + make compliance simple

Set-up environmental, safety or any other compliance threshold and trigger alerts. Use automation + control to alert employees, shutdown machinery, and prevent HSEC breaches.

Predict maintenance needs, prevent failures + extend asset lifespan

Continuously monitor your assets' performance to predict failures and schedule maintenance. Keep assets running for longer, reduce unplanned maintenance, and prevent downtime.

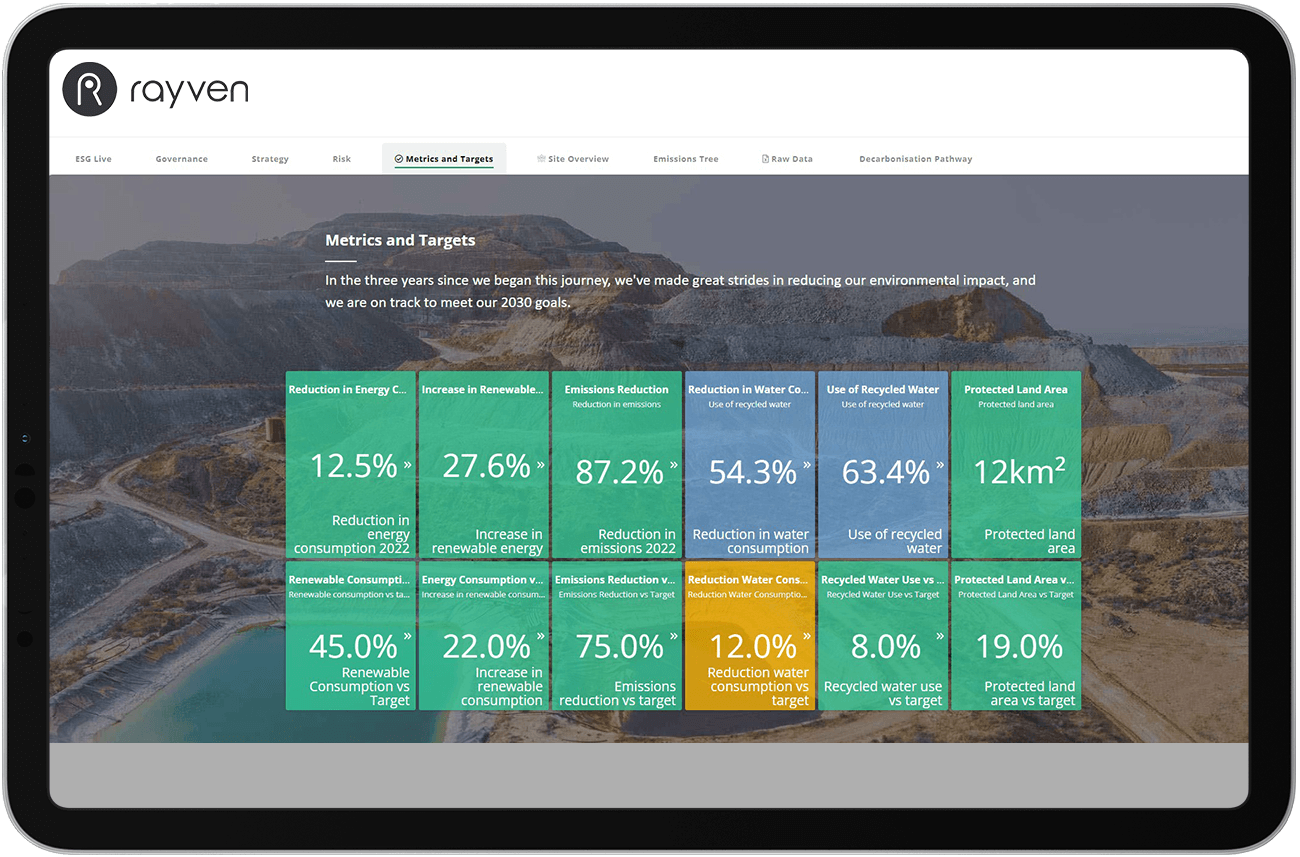

One-click sustainability

reporting

Capture, collect + trace all your HSEC data from anywhere to understand performance. Get easy, 1-click reporting against key sustainability frameworks + standards.

Fits all your existing

hardware + technologies

Our Quarry Monitoring solutions can integrate with any machinery, system, hardware, sensor, technology, or data repository - you don't need to buy new assets.

Increase yields, efficiency + profitability

Use real-time insights from machinery and the field to optimise operations. Improve key metrics such as load volumes, loading, material density, carry-back + more.

Fast-to-deploy,

infinitely scalable

Deploy our Quarry Monitoring solutions at a single site or with select assets, add more over time and build-in automation, machine learning + AI capabilities.

How Rayven works with you to deliver, fast.

How Rayven creates your solution in weeks:

After onboarding and a thorough discovery process with you and your team, we'll utilise our tried and tested solution delivery model.

1: We connect to what you already use

Asset systems, site tools, safety platforms, plant data, sensors, project tools, files - whatever you use - united. No rip-and-replace.

2: We make your operational data usable

All your data is cleaned, stored + made available within Rayven, so that all your teams and systems have access to it.

3: We build the logic, dashboards + alerts

We create the things you'll need, from custom UIs and reports, through to the logic, AI and automations that deliver it.

4: We run it, add capabilities/AI + scale

We don't just deliver it and forget; we'll support your use with 24/7 support, updates + work with you to develop your solution.

We unite data, automate actions + build Quarry Monitoring solutions with real-time and AI capabilities that work with all your existing technologies.

See Rayven in-action:

Book a 1-on-1 demo with one of our Australia-based experts, tailored to your needs.

Why Rayven costs less than enterprise solutions.

Mid-market operations need serious systems, but not the cost and chaos that come with traditional enterprise software.

Rayven delivers the same outcomes with a radically lighter footprint + much, much faster.

Everything you need in one platform.

Data, apps, automation + everything to run them. One license.

We own, build + run our own technology.

No resellers or third-party mark-ups; new capabilities are aligned to industry.

Delivered for you by our specialists.

We design, build, deploy + support - you don’t need internal developers.

Small-footprint deployments that scale.

We can start small, expand across sites + teams without engineering or lock-in.