In the world of industrial technology, legacy systems often represent a significant hurdle. They're like anchors, holding businesses back from achieving the full potential of digital transformation. Yet, these systems are vital, containing critical data and functions essential to operations.

The challenge lies in bringing these dated infrastructures into the modern era, transforming them into smart, interconnected ecosystems. This is where Internet of Things (IoT), Data Science, and Artificial Intelligence (AI) technologies can play a pivotal role. By adopting hybrid platforms, like the Rayven Platform, you can breathe new life into legacy systems, turning them into dynamic components of a forward-thinking industrial operation.

The Challenge with Legacy Systems.

Legacy systems are ubiquitous in industries the world-over. They're often robust and have stood the test of time but come with their own set of challenges, however they can be inflexible, struggle to integrate with newer technologies, and typically operate in silos. As a result, they create significant barriers to innovation and efficiency.

The main issues with legacy systems include:

- Integration/Interoperability Difficulties: Many legacy systems were not designed to communicate with other technologies, making data sharing and system coordination a complex task.

- Data Accessibility Issues: Retrieving and utilising data (ETL and data analysis) from these systems can be a laborious process, often requiring manual intervention and leading to delays in decision-making.

- Maintenance + Security Risks: Older systems can be expensive to maintain and may not meet current security standards, posing risks to business operations.

Despite these challenges, it’s not always feasible, nor sensible, to completely replace these systems. They often represent a significant investment and are embedded into the core processes of a business. The solution, therefore, lies not in replacement, but in transformation.

Data Science, IoT and AI as a Solution

The integration of Data Science, IoT and AI technologies offers a powerful solution to the challenges posed by legacy systems.

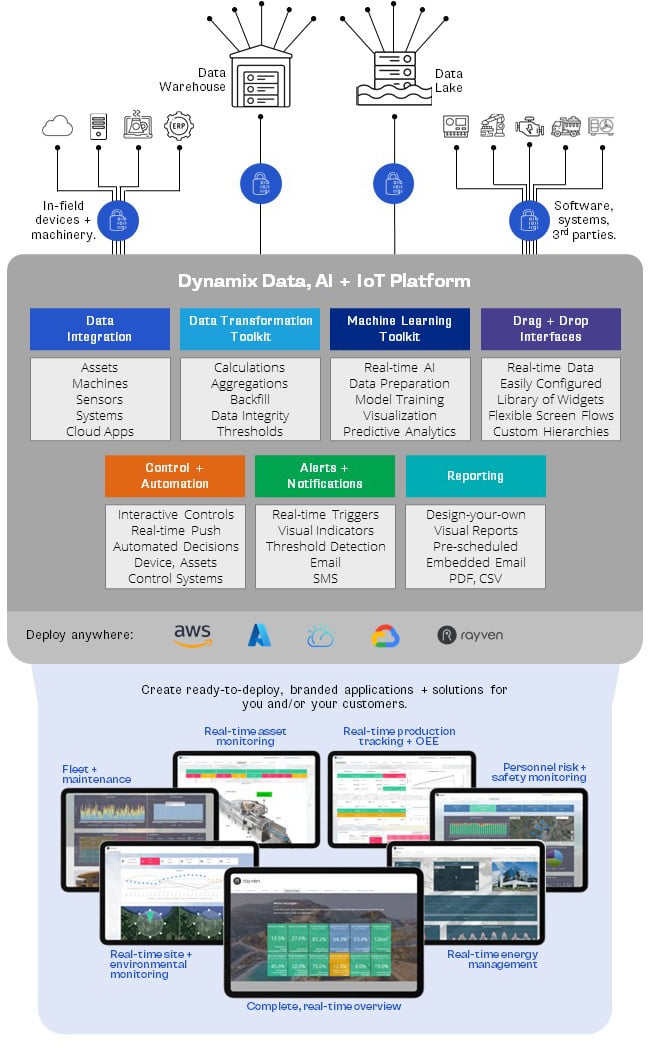

Integrated data, AI + IoT platforms stand out in their ability to weave these advanced technologies into existing industrial frameworks, effectively transforming them into intelligent, interconnected ecosystems.

- Integrating IoT for Enhanced Connectivity: IoT serves as the bridge between physical operations and digital capabilities. By outfitting legacy systems with IoT sensors and devices, integrated data, AI + IoT platforms enable real-time data collection and analysis. This transformation allows for a deeper understanding of system performance and opens the door to enhanced operational insights.

- Seamless Integration with Existing Systems: One of the key strengths of integrated data, AI + IoT platforms is its ability to integrate seamlessly with existing business systems, data stores, and third-party systems via APIs or alike. This integration respects the value and role of these systems, provides valuable operational-relevant and business data, all whilst enhancing their functionality and bringing them into industrial operations in real-time.

- Leveraging AI for Smarter Operations: The integration of AI takes this a step further. Integrated data, AI + IoT platforms use machine learning algorithms to analyse the data collected, identifying patterns and predicting outcomes. This capability enables proactive maintenance, optimising resource allocation, and improving overall operational efficiency.

Diagram: how integrated data, AI + IoT platforms integrate and deliver new Industry 4.0 capabilities.

Practical Applications and Benefits

The transformation of legacy systems through IoT and AI has practical and tangible benefits for industrial operations. By utilising integrated Data, AI + IoT platforms, businesses can achieve:

- Enhanced Efficiency + Productivity: With real-time data monitoring and AI-driven insights, operations become more efficient. This leads to a reduction in downtime, improved resource utilisation, and higher overall productivity.

- Simple, accurate reporting at all-times: leveraging real-time data and crafting custom dashboards, you can make reporting simple and meet compliance standards, simply.

- Cost Savings + Risk Mitigation: The proactive approach enabled by IoT and AI integration reduces the need for emergency repairs and maintenance, leading to cost savings. Additionally, up-to-date security protocols mitigate the risks associated with older systems.

- Improved Safety + Sustainability: These new technologies make it simple for businesses to prevent incidents and achieve environmental standards, all whilst accurately tracking emissions and achieving both safety and sustainability credentials.

- Scalability + Future-Proofing: As businesses grow and evolve, the flexibility of Rayven's platform ensures that legacy systems can scale and adapt. This scalability not only addresses current needs but also positions businesses to easily incorporate future technological advancements.

The integration of IoT and AI technologies with legacy systems is not just a mere upgrade; it's a complete transformation, turning outdated infrastructures into dynamic, intelligent components of a modern industrial operation.

The Rayven Platform is at the forefront of this transformation, offering a pathway to revitalise legacy systems, enhance operational efficiency, and future-proof businesses in an ever-evolving technological landscape. By embracing these advancements, industries can transcend the limitations of the past and step confidently into a future of smart, interconnected operations.