Pump Monitoring solution: get real-time performance + maintenance insights that reduce costs.

The problem.

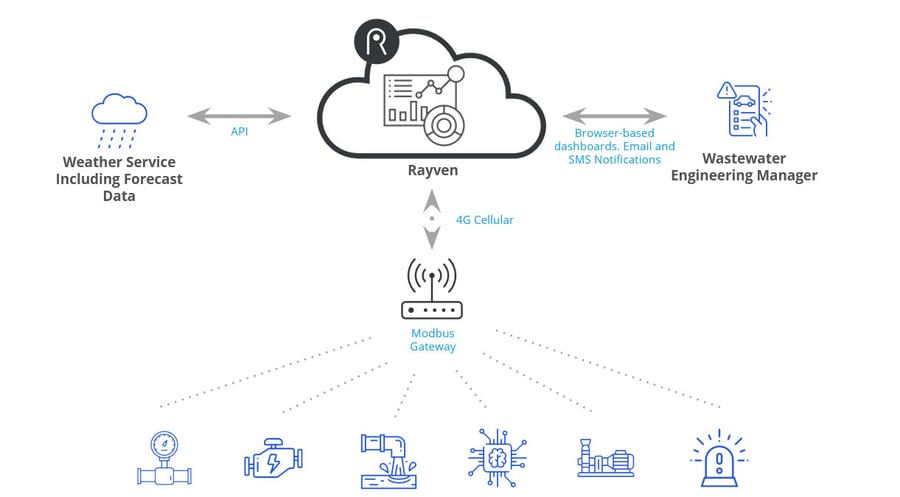

Wastewater pumping stations are an intrinsic part of the sewerage network, raising sewerage from gravity-fed pits to extend transmission over longer distances. As such, they’re often located in built-up urban areas, operate regularly and can quickly cause problems when they fail.

What’s more, they’re also often ‘old infrastructure’ that have only been augmented over time with newer equipment as pieces fail, rather being continuously invested in and modernized.

In addition, there’s lots of machinery involved. This makes monitoring the sites’ pumps, extraction fans, and waste pits is an arduous and manual process full of inefficiencies requiring site visits by expensive resources, even when there aren’t any current or forthcoming issues.