Cold Chain Fleet Management IoT Solution: improve your supply chain and increase customer satisfaction through real-time DIFOT.

The problem.

Our client is a cold chain logistics company that delivers perishable goods from farm to supermarket. This makes fast delivery, undamaged product, and ensuring that goods arrive at the correct temperature are important factors for their end-customers.

Traditional methods of customer service performance measurement include it being assessed on receipt or being measured after the fact (e.g. a temperature logger that shows an alert once already received), which can make it hard to know where your supply chain failed, especially if you don’t use ‘Sign on Glass’ to record delivery times or if the temperature is reported after delivery to the customer’s dock.

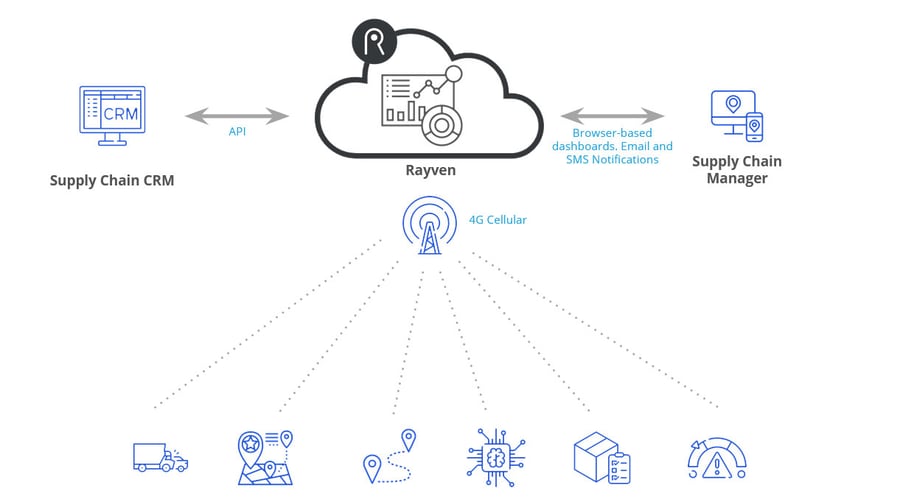

This is where Rayven’s Cold Chain Fleet Management IoT solution can help.