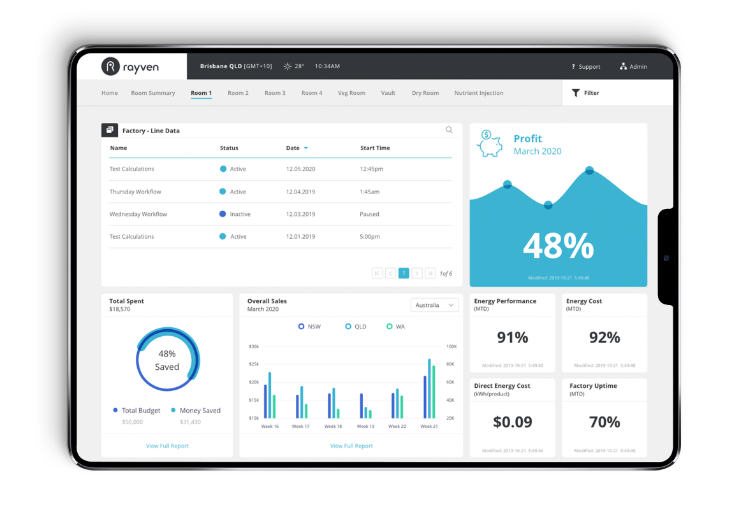

Electricity Distribution Monitoring Solution: improve the longevity, resilience + performance of power networks.

The problem

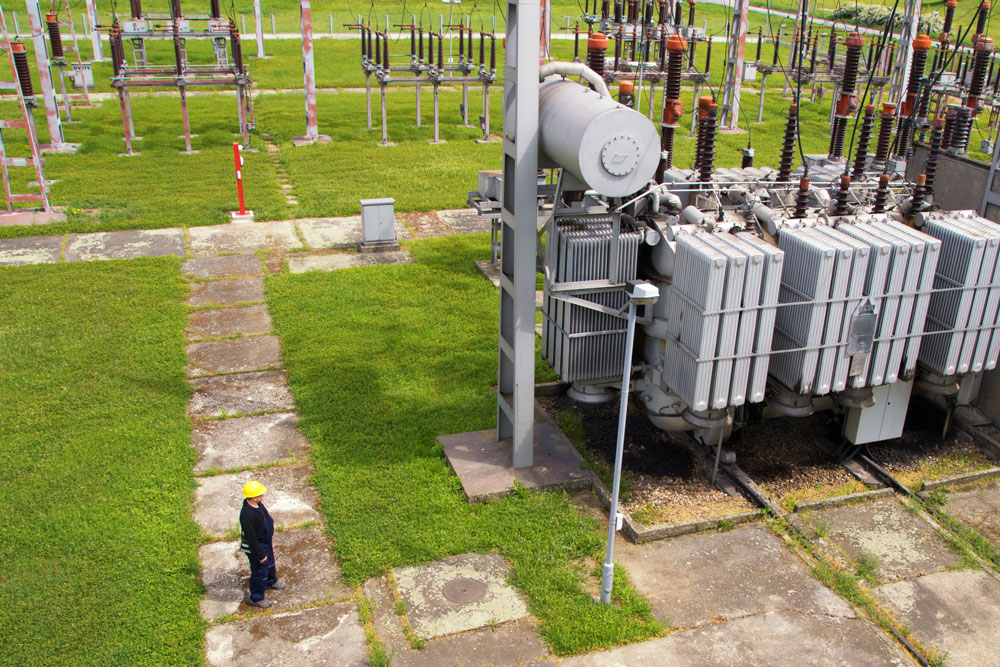

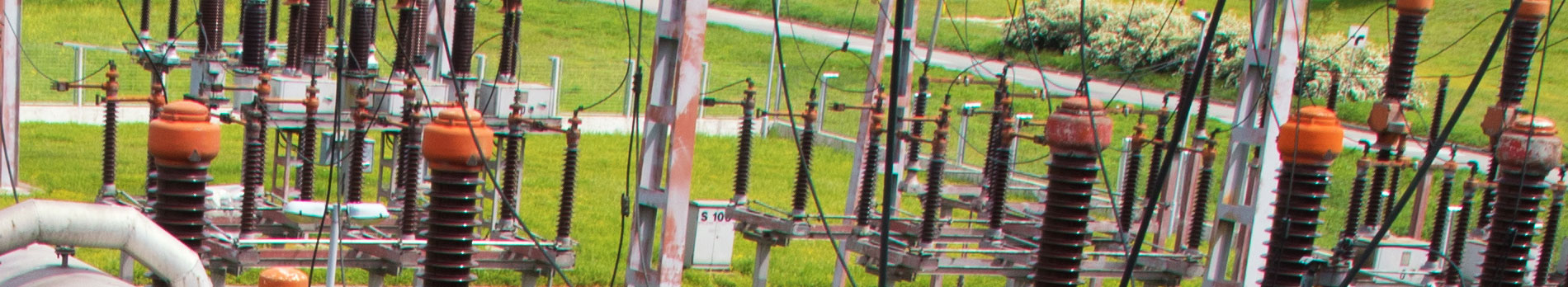

Distribution transformers are one of the main component of our power grids and as such, they need to be adequately maintained to prevent them from failing and to ensure that power is reliably and adequately transmitted at a rated voltage without interruption. Outside of causing blackouts, a poor quality power supply will result in increased power and production losses to the suppler, as well as cause other equipment to be damaged or fail, reducing it’s lifespan.

Detecting problems and fixing them rapidly before they become failures or can cause broader damage is, therefore, critically important for both utility companies and their end-customers – which is where Electricity Distribution Monitoring Solution can help.