Farming Automation solution: do more with less and be ready for the future.

The problem.

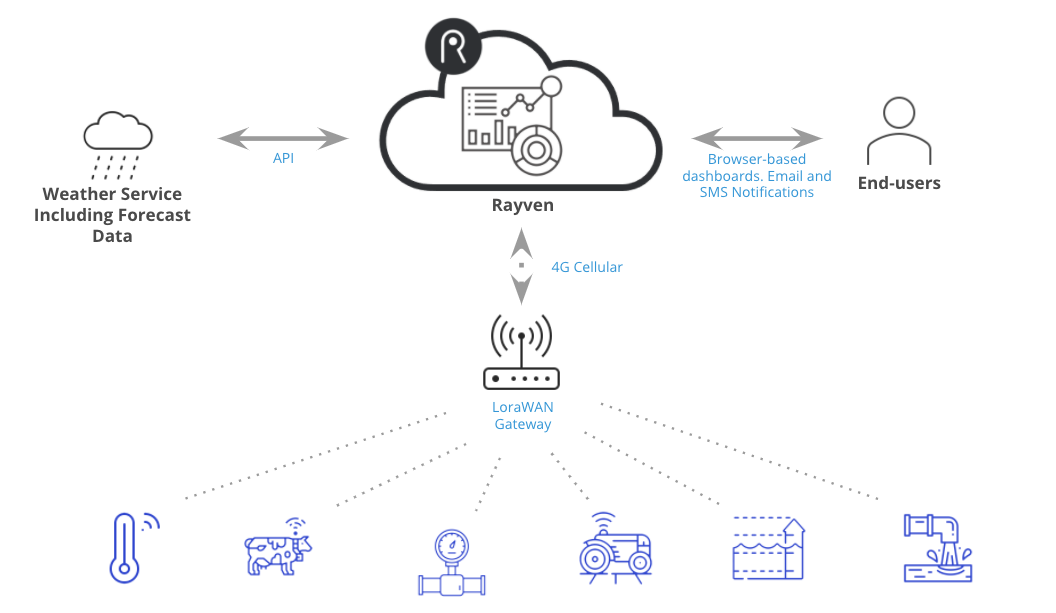

Farming Automation solutions will help farmers solve the current and forthcoming crises that are on the horizon.

As climate change drives more and more unpredictable weather patterns, and operational costs increase, it has become much harder to leverage generational practices to produce yield and profitability.

If you then include variable elements like crop type, existing irrigation technologies, and geography (to name but a few) into the mix with a changing environment, then you have a melting pot of increasing complexity that you need to make sense of.