Real-time OEE solution: understand + improve output in real-time.

The solution.

Overall Equipment Effectiveness (OEE) measures the six big causes of lost production, providing organisations with an overall measure of asset utilisation. The problem is, measuring OEE accurately, consistently and at any given moment can be incredibly difficult for manufacturers.

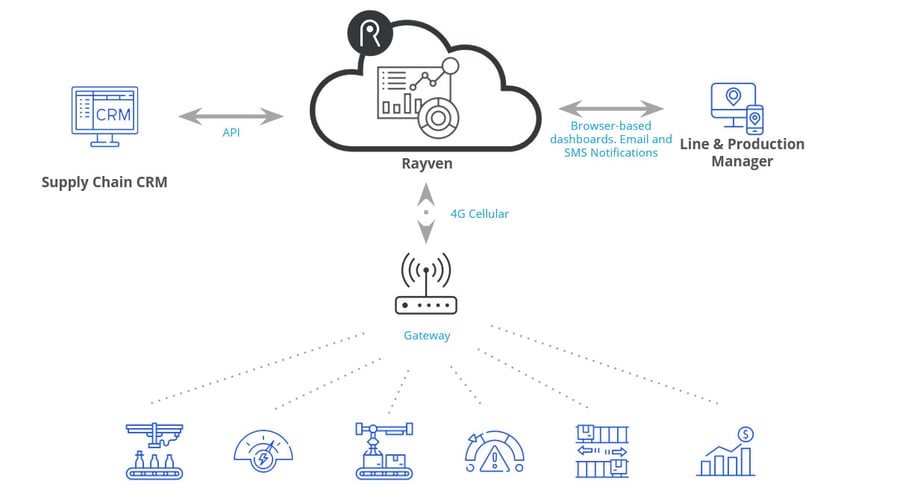

That’s why Rayven came together with the client’s continuous improvement team to implement a Real-time OEE solution (built on our Rayven Platform), to monitor their OEE in real-time, providing a custom view for the causes of loss and web tools for the people on the factory floor to enter the reasons for downtime. This would enable them to establish an accurate OEE baseline calculation, and then identify and implement both reactive and proactive enhancements, fast.

Defining what data to collect is critical.

In order to create a Real-time OEE solution that can provide the insights needed to increase OEE, we started by identifying the key metrics required to measure them. In this solution it included:

- Hourly and daily targets

- Machine status

- Shift schedules

- Real-time throughput

- Downtime reasons

- Production schedule.

Initial goals of the Real-time OEE solution.

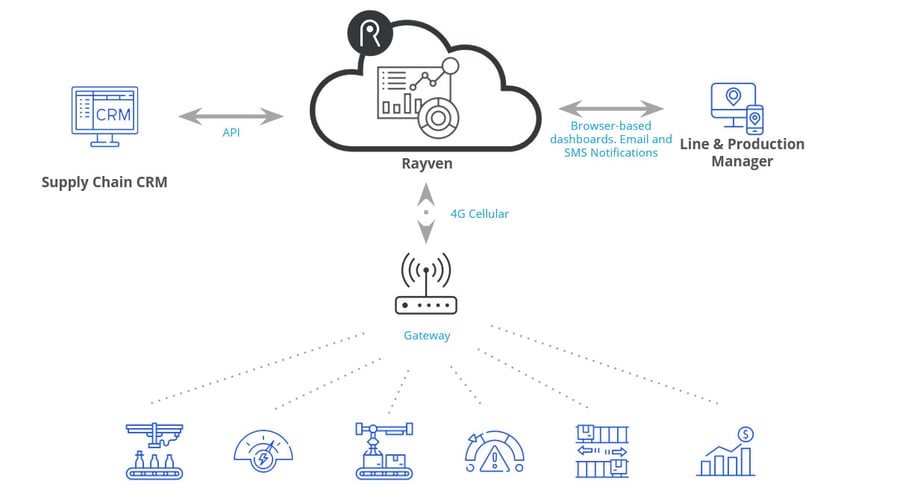

The first goals of the real-time OEE solution were to focus on connecting to a range of data sources on the factory floor. This included installing proximity sensors and PLCs to track movements of product along the production line without interfering with the proprietary controllers, and ERP to have visibility around shifts schedules and production targets. All of this data was to be collected in real-time and sent to the Rayven Cloud where it would be compared with the data from the factory floor to ensure data quality and integrity. This would deliver the following solution features:

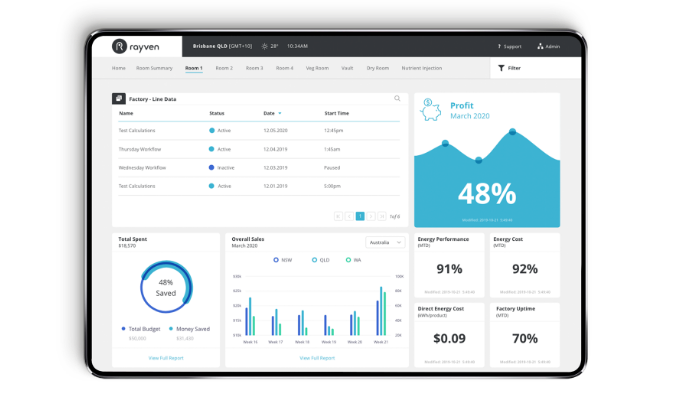

- Monitoring of critical operational data received from the equipment via a web-based and mobile system

- Device management monitoring of PLCs and Gateways that are in place

- Ability to define business logic to reach the organisation’s OEE rules

- Provide alarm and alert notifications via email or SMS messages when there was downtime, or when OEE below target

- Deliver real-time OEE metrics on iPads on the factory floor as well as the capability to input downtime reasons

- Connection with the ERP system to collect daily targets and shift schedules

- Test the application, making sure all of the above goals are met, based on the below solution architecture:

Before setting the solution live, we tested four critical aspects of the Real-time OEE solution:

Security.

Our Rayven Platform is built with security as a top priority and our proprietary security architecture ensures that data is secure at all points of the environment.

The real-time OEE solution includes data encryption in transit from device-to-cloud, as well as device authentication; security (Bearer) tokens; SSL, AES and RSA encryption; as well as additional device security checks done via automated polling.

Connectivity.

Once the proximity sensors were installed and connected to PLCs, a Wi-Fi connection to a 4G Gateway proved to be the best solution. The combination of a secure and encrypted transmission path together with a dedicated, direct connection (that eliminates the need to connect to the factory’s network) meant that a fast and secure connection could be established without the need to involve IT.

Data integrity.

Once connectivity was established and data started flowing consistently to the Rayven Cloud, the next important process was to validate that the data from the factory floor matched the data being processed in the Rayven Platform. In addition, all of the business logic and calculations were tested to ensure that decisions would be made based on reliable, accurate information

Industrial data science.

The objective of exploratory data analysis was to observe trends in the data and compare them with what was happening on the factory floor, which included:

- Real-time OEE by shift, day, line, and product

- Dual and target shift production displayed as pitch charts

- Cost of downtime

- Shift efficiency, based on targets and shift comparison

- Reasons for downtime trends, by shift, day, line, and product.

What’s next?

After providing initial insights, optimisation alterations were made accordingly and the factory is now in the planning phase to expand the real-time OEE solution to additional lines and into three other facilities, with the goal of providing a cross-facility view for senior management.