Wastewater Facility solution: implement real-time asset monitoring, improve energy efficiency + predict maintenance needs.

The solution.

Wastewater pumps must be protected from downtime and faults in order to keep up with the need to move waste water around facilities without interruption. Water pump failures are a significant issue and disruptive to both customers and water companies, so being able to not just monitor them to identify problems quickly, but predicting failures before they occur is hugely desirable.

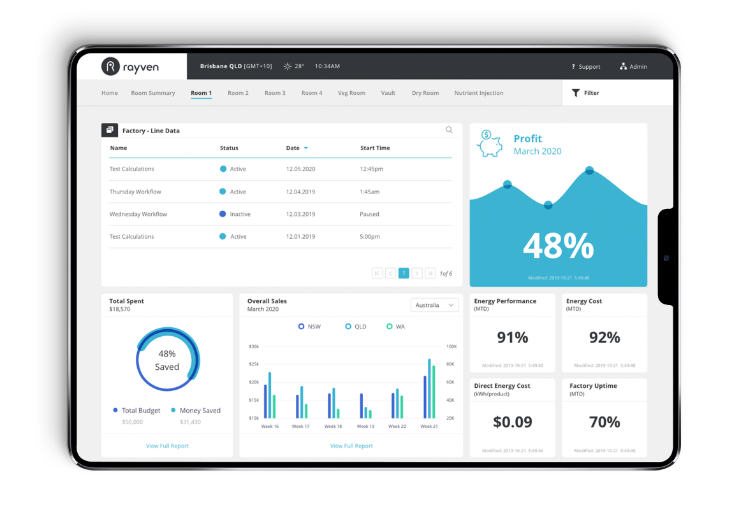

We designed and implemented a Wastewater Facility solution, built on our world-leading Rayven Platform, that enabled our client to collect real-time data from the water pumps’ PLCs, weather reports and from 4G energy meters, before combining data sets to identify new performance metrics, maintenance insights and improve fault detection, creating an extremely flexible solution.

Defining what data to collect is critical.

In order to create the Wastewater Facility solution, we started by identifying the data needed to deliver on the customer’s goals. In this solution, this included:

- Energy consumption

- Water pump status

- Current and predicted temperature and moist

- Oil level

- Energy consumption

- Energy pricing

- Water flow rate.

Initial goals of the Wastewater Facility solution.

The first goal of the Wastewater Facility solution was to focus on connecting the waste water pumps, PLCs and external weather service to the solution in order to collect data in a consistent and reliable manner, ensuring its data quality and integrity. To achieve this, we provided the following features:

- Monitoring of critical operational data received from the equipment via a web-based system

- Device management

- Creating business logic for the application to meet the business objectives

- Providing alarm and alert notifications via email or SMS messages

- Collection of historical data to enable energy consumption forecasting and fault detection

- Multiple dashboards to provide the right users with the right insights

- Testing of the application, making sure all of the above goals are met, based on the below solution architecture:

.jpg?width=817&height=452&name=water-pump-diagram%20(1).jpg)

Before go-live, we tested four critical aspects of the Wastewater Facility solution:

Security.

The Rayven Platform is built with security as a top priority.

Rayven’s proprietary security architecture ensures data is secure at all points of the environment. The Wastewater Facility solution includes data encryption in transit and is encrypted from device to cloud (device-dependent). Devices are authenticated using device keys (device-dependent) and 256-bit SSL encryption is used between end-user devices (PCs, tablets, mobile phones) and the cloud, which protects confidentiality, integrity and availability of data in transit from device to cloud.

Connectivity.

Once securely connected, PLC’s were connected via a Modbus connection to the 4G energy meter, which acts also as a gateway, and temperature sensors and moisture sensors were set up. The combination of a secure and encrypted transmission path, together with a dedicated and direct connection to the 4G gateway, meant a fast and secure connection could be established without needing to involve their IT team.

Data Integrity.

Once all the sensors were connected to the gateway and transferring data to the platform, it was critical for us to test that the raw data on the machines and sensors matched the data in the dashboards, meaning that the connection (and the sensors) was operating effectively. In addition, it was critical to build-in capability to back-fill data in sequence in the event that communication ever goes down, so that there would never be gaps in data flows to the Wastewater Facility solution.

Industrial Data Science.

The objective of the exploratory data analysis was to identify trends in the data, which included:

- Energy usage patterns compared with water flow data

- Pumping vs. water flow pressure

- Pump energy efficiency

- Anomaly detection

- Water pump maintenance and failure alerts.

What’s next?

We are continuing to gather additional data and growing the data sets so that we can improve the Wastewater Facility solution's energy forecasting, fault detection and predictive maintenance capabilities.

.jpg?width=817&height=452&name=water-pump-diagram%20(1).jpg)