Pain-point 5:

Building custom applications is hard and / or expensive.

Go beyond dashboards and add all-new, highly-customised capabilities to monitor + improve.

Integrating and analysing all of your data in real-time is the first key step in improving operational outcomes using data, but delivering the capabilities to then do something with it can transform them; raising performance to a whole new level.

Our Rayven Platform makes it easy for you to create user-friendly, highly-customised applications that enable users to improve what they do in one place.

This could be as simple as enabling someone to improve how infield devices' are managed and maintained remotely, through to creating solutions that deliver touch-screen tools that control machines so that you can seize productivity or efficiency benefits remotely, simply.

Related business

symptoms:

Technical Rigidity: Challenges in developing custom applications lead to limited adaptability, hinders the adoption of novel technologies due to their poor fit/expense involved adopting them, or sees a plethora of single use solutions.

High Development Costs: Reliance on non-optimised systems and a lack of multi-use systems results in inefficiencies, higher costs, and subpar performance.

Data Integration Issues: Inability to create tailored applications impedes effective data integration and utilisation, meaning you see errors and data drop-outs which affect real-time decision-making and process optimisation.

Join the teams big + small already achieving more with Rayven:

How the Rayven Platform solves it.

Rayven makes it easy to build multiple, multi-use solutions on a single instance of the Rayven platform. The seamless design of the platform means that it's not only simple to use, but that you only need the Rayven platform rather than a raft of systems to do the same job.

Create custom

workflows + logic:

Our Workflow Builder, featuring a drag-and-drop interface, makes it possible to create rules, connect systems, and put in place sophisticated business processes that sit behind your solutions; effectively programming a custom integration + real-time data + application - all without writing a line of code (unless you want to!)

The codeless interface enables you to combine different data sources, perform complex calculations, add AI and automations to solutions, as well as create data visualizations, alerts, reports... the list is almost endless.

Create real-time, white-labelled interfaces using 40+ data visualizations + widgets:

Pre-built and highly-customisable using drag-and-drop, you can easily configure user interfaces for those in the boardroom and in the field, making them available to individuals, groups or business-wide with simple user management.

What's more the integration, real-time data + apps you build can be fully-white labelled to fit your (or your customers') brand.

Add virtual controls + user-controlled

optimisation capabilities:

Our platform not only enables you to create beautiful dashboards and user interfaces, but it also enables end users to do something with the data and take control of assets, processes, and machinery remotely.

This could be as simple as shutting down failing machinery, through to giving them a set of virtual controls to finetune performance and optimise throughput.

Add insights, user guidance +

predictive analytics in situ:

Rayven enables you to give operators real-time suggestions and insights as they're using not only the Rayven Platform, but also through interconnected machinery and systems (where it is supported).

This means users can not only see real-time performance, but get advice on how it can be improved, as well as deliver accurate forecasts and models to where it could be should optimisations be made.

The step-by-step.

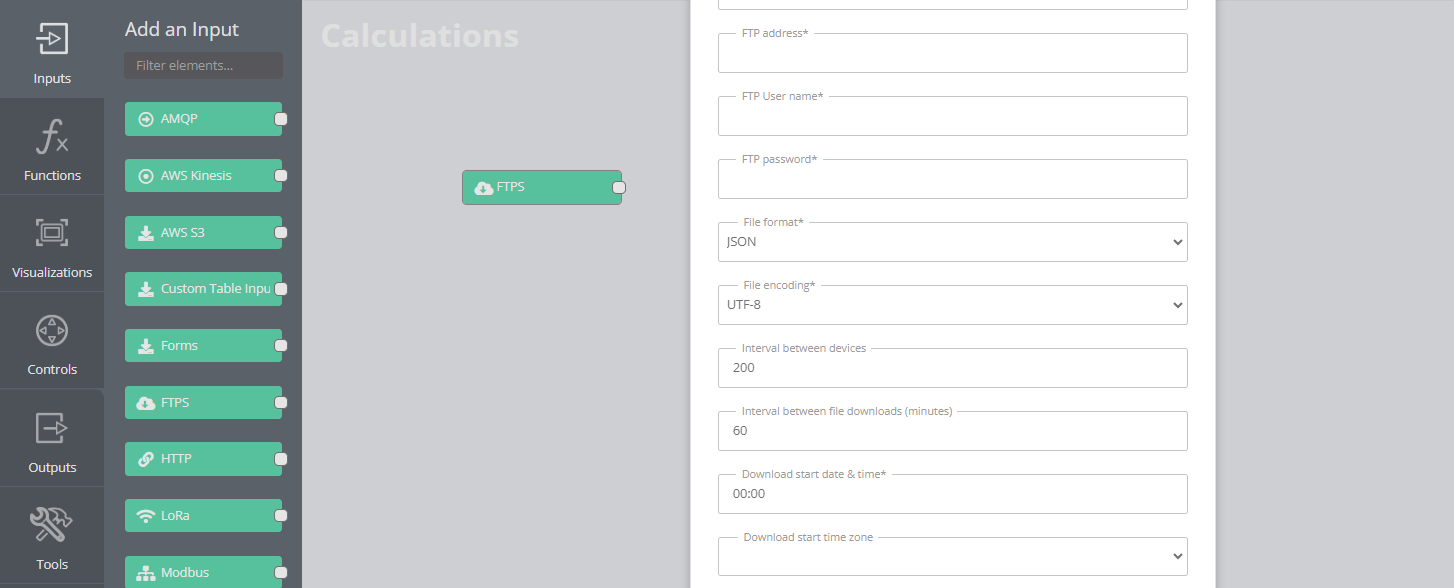

Step 1: Connect

Our platform has out-of-the-box integrations with major platforms and 20+ universal connectors (nodes) that work at the protocol-level + are easy to configure, enabling you to connect any data feed and system.

Our platform's approach enables bidirectional data flow in the native protocol of each connected device in various formats, including JSON, XML, CSV, plain text, and more.

Step 2: Process, Normalise, Store + Access

Following ingestion, data undergoes processing which includes validation, normalisation, and potentially transformation, aligning it with a standardised format for analysis and storage.

The processed data is then stored in scalable and secure databases or data lakes, which is adaptable for cloud or on-premises setups.

Step 3: Build Interfaces

You can build custom, interactive dashboards for different users, giving them access to the platform's tools and data visualizations through any device, and enabling them to drilldown into data sets and sources, anywhere.

Equipped for complex data analytics, the platform enables functionalities like Big Data analysis using Machine Learning, predictive analytics, and Digital Twin modelling all through our dashboards.

You can also create standard, scheduled pdf reports that are automatically created and sent to selected users that display the data that you need.

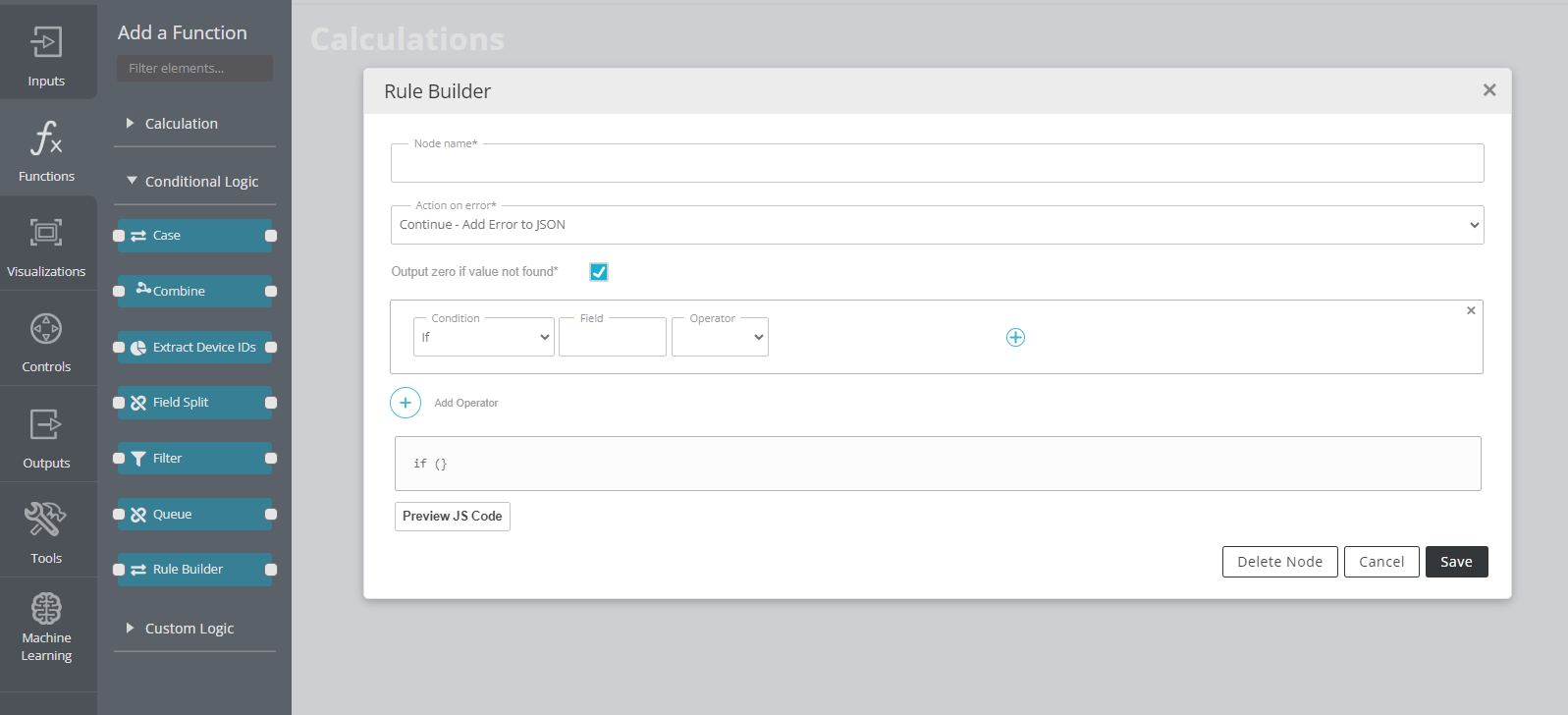

Step 4: Create Rules + Logic

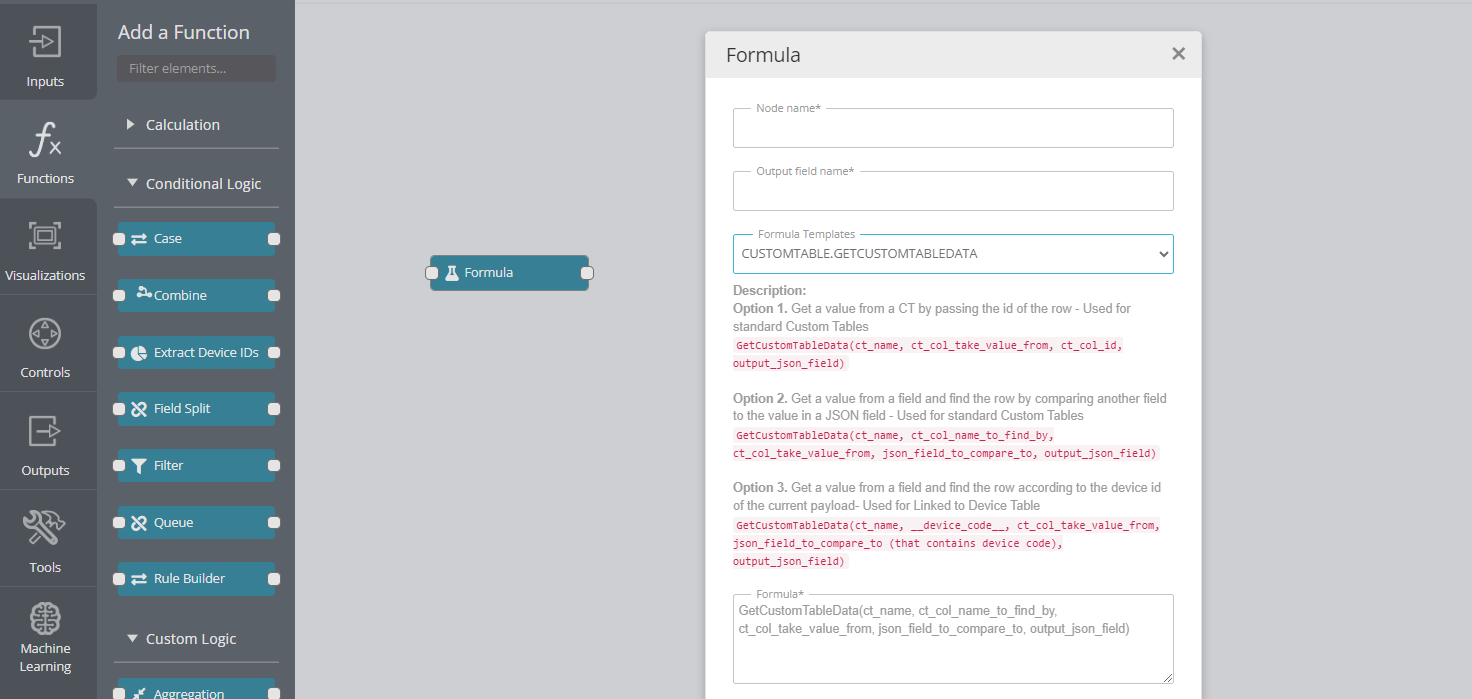

Use some of our advanced rule nodes to create complex multi-step rules using a simple codeless interface. Use to add:

- Create logic using IF, AND, OR, ELSE, ELSEIF, and THEN

- Produce nested logic

- Act on fields, including field modifiers [[varName(-1)]]

- Lookup values from custom tables

- Apply operators (=,<,>, ≤, ≥, ≠, between, and not between)

- Output multiple variables

The node produces a sample JavaScript so that advanced users can verify the logic.

Step 5: Add Formulas + Machine Learning

The wide verity of Output node enables you to push information from Rayven to other applications. It can send either specific fields or the entire JSON content to another system, or even create and push a CSV file.

You can also customise output data using columns, which adds a field to the data that is to be accessed via API to help it find the right data to act upon.