Vibration Monitoring Solution

Detect anomalies in real-time, optimise maintenance + prevent breakdowns simply.

We rapidly create and deliver custom Vibration Monitoring solutions for industry that delivers real-time, traceable performance, uptime, and cost improvements - fast + affordably.

Monitor vibrations on any plant and assets, predict failure + keep operations moving via a custom, real-time solution.

Take asset and machinery monitoring to the next level using our advanced vibration monitoring solution tailored for businesses.

Using our Rayven platform and proven solution templates; we integrate in-field devices, systems + assets to deliver real-time and predictive insights to the people who need them, anywhere.

With universal integration, machine learning, automation + AI built-in; a Rayven solution helps you to detect potential problems, streamline maintenance schedules, and optimise overall equipment performance.

Remote, real-time vibration monitoring from anywhere

Predict maintenance needs + prevent failures

Build interactive dashboards + drill into trends

Add custom AI + universal automation

Fits all existing

hardware + technologies

Add additional vectors, including heat, noise + speed

Monitor assets for excessive vibrations. Integrate real-time data sources from sensors, systems, and machinery software to get the complete, real-time view.

Set-up normal performance thresholds, alert employees of anomalies, and create custom automations and logic that shuts machinery down before major failures.

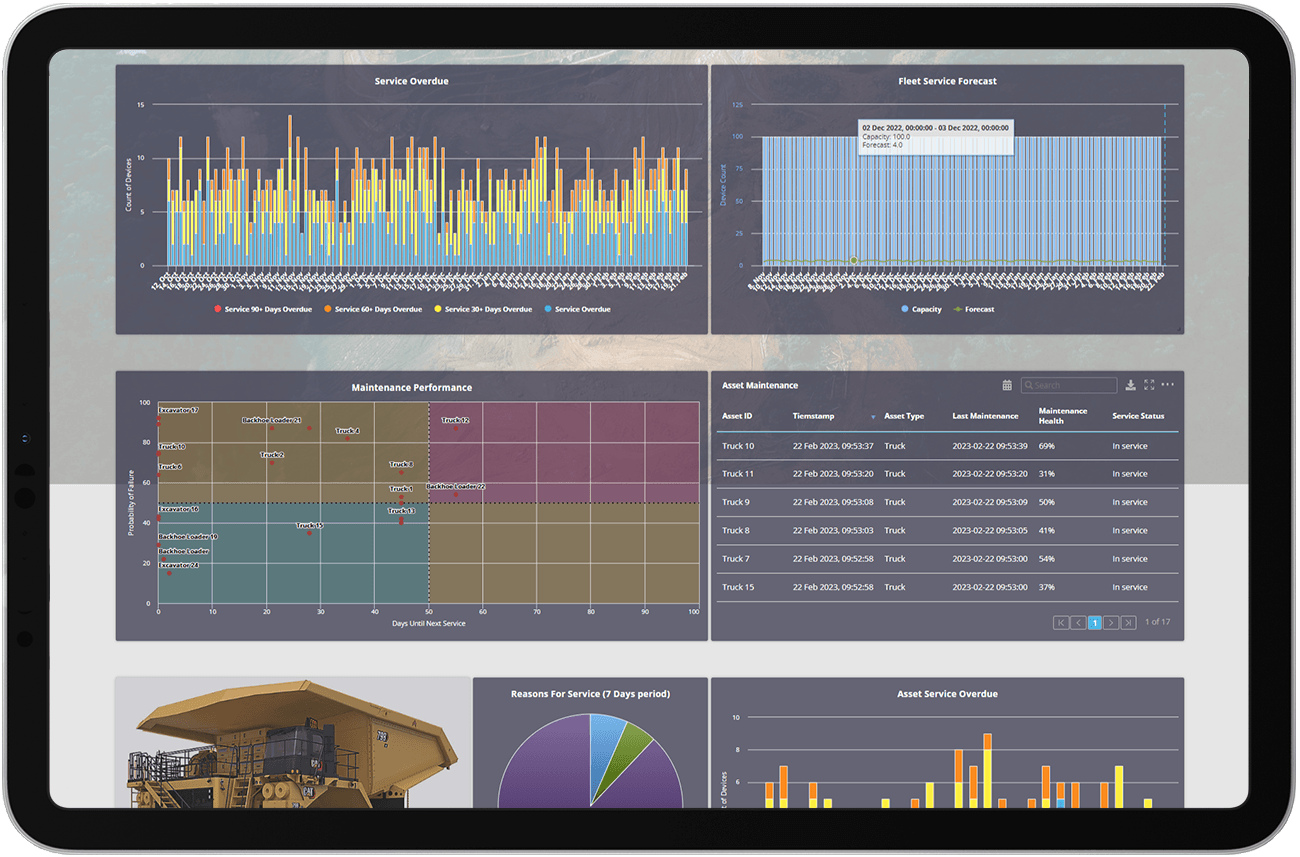

Build custom dashboards to explore individual asset's and fleets' performance. Explore potential causes, how other variables interact, and analyse historical data sets, fast.

Our solution enables you to use predictive analytics with your real-time data to predict future performance and maintenance needs.

Our vibration monitoring solution will integrate with any machinery, system, hardware, sensor, technology, or data repository - guaranteed

Incorporate different in-field sensors to develop a complete, real-time view of machine performance + enhance predictive modelling.

How Rayven works with you to deliver, fast.

How Rayven creates your solution in weeks:

After onboarding and a thorough discovery process with you and your team, we'll utilise our tried and tested solution delivery model.

1: We connect to what you already use

Asset systems, site tools, safety platforms, plant data, sensors, project tools, files - whatever you use - united. No rip-and-replace.

2: We make your operational data usable

All your data is cleaned, stored + made available within Rayven, so that all your teams and systems have access to it.

3: We build the logic, dashboards + alerts

We create the things you'll need, from custom UIs and reports, through to the logic, AI and automations that deliver it.

4: We run it, add capabilities/AI + scale

We don't just deliver it and forget; we'll support your use with 24/7 support, updates + work with you to develop your solution.

We unite data, automate actions + build Vibration Monitoring solutions with real-time and AI capabilities that work with all your existing technologies.

See Rayven in-action:

Book a 1-on-1 demo with one of our Australia-based experts, tailored to your needs.

Why Rayven costs less than enterprise solutions.

Mid-market operations need serious systems, but not the cost and chaos that come with traditional enterprise software.

Rayven delivers the same outcomes with a radically lighter footprint + much, much faster.

Everything you need in one platform.

Data, apps, automation + everything to run them. One license.

We own, build + run our own technology.

No resellers or third-party mark-ups; new capabilities are aligned to industry.

Delivered for you by our specialists.

We design, build, deploy + support - you don’t need internal developers.

Small-footprint deployments that scale.

We can start small, expand across sites + teams without engineering or lock-in.

Vibration Monitoring solution FAQs.

Question: What is vibration monitoring, and why is it important?

Vibration monitoring refers to the process of measuring and analysing vibrations produced by machinery and equipment, particularly in industrial settings. It is crucial for detecting early signs of mechanical issues, optimising maintenance schedules, minimising downtime, reducing costs, and improving overall equipment performance.

Question: What industries can benefit from vibration monitoring solutions?

Industries such as manufacturing, power generation, oil and gas, mining, and transportation can benefit from vibration monitoring solutions. Any sector where machinery and equipment health is vital to operations can utilise vibration monitoring to maintain optimal performance and reduce potential failures.

Question: How does an IoT-based vibration monitoring system work?

IoT-based vibration monitoring systems use connected devices, such as sensors, to continuously measure and track vibrations in real-time. The data collected by these devices is sent to a central platform for analysis and reporting, enabling businesses to make informed decisions and implement effective maintenance strategies.

Question: What are the key features to look for in a vibration monitoring solution?

Essential features to consider in a vibration monitoring solution include real-time data collection, accurate and reliable sensors, user-friendly data visualisation and reporting tools, alerts and notifications for potential issues, and the ability to integrate with existing systems and processes.

Question: How can real-time vibration monitoring help improve equipment maintenance?

Real-time vibration monitoring enables businesses to detect potential mechanical issues before they escalate, allowing for proactive maintenance and preventing costly equipment failures. By optimising maintenance schedules based on actual equipment health, businesses can minimise unexpected downtime, maximise uptime, and reduce maintenance costs.

Unlocking the power of real-time vibration monitoring in industrial applications.

Real-time vibration monitoring, powered by IoT technology, offers a proactive approach to managing equipment health and performance; and can be used for multiple applications that compound the benefit of any site-wide vibration monitoring solution.

- Early detection of equipment issues: Vibration monitoring enables businesses to identify early signs of mechanical issues in machinery, such as bearing wear, misalignment, or imbalance. By detecting these issues before they escalate, companies can prevent costly failures and extend equipment lifespans, as well as minimising downtime and maximising uptime.

- Optimised maintenance schedules: Traditional preventive maintenance schedules are set at fixed intervals, which in turn can lead to unnecessary or untimely servicing. With IoT-based vibration monitoring, businesses can transition to a condition-based maintenance approach, where maintenance is performed based on the actual health of equipment. This data-driven strategy reduces maintenance costs, optimises resource allocation, and prevents unexpected breakdowns.

- Improved Overall Equipment Effectiveness (OEE): Monitoring vibrations in real-time can contribute to improved overall equipment effectiveness. By identifying potential issues, optimising maintenance schedules, and reducing downtime, businesses can maintain high levels of equipment performance and availability.

- Enhanced worker safety: Unexpected equipment failures can pose significant safety risks to workers in industrial environments. Real-time vibration monitoring helps mitigate these risks by detecting mechanical issues before they escalate and even shutting down machines before a catastrophic and hazardous failure.

- Seamless integration with existing systems: IoT-based vibration monitoring solutions can be easily integrated into existing systems and processes. With user-friendly data visualisation and reporting tools, businesses can quickly access and analyse vibration data alongside other critical operational metrics. This comprehensive view of equipment health and performance enables informed decision-making and drives continuous improvement.