Petrol Station Monitoring Solution: Transforming asset management across a gas station network.

The problem

Most gas stations combine fuels storage and pumping, a retail store and self-service areas, too. That means managing the use of tanks, pumps, air compressors, refrigeration, HVAC and lighting – all of which are consuming energy and adding to a sizeable electricity bill.

Not only that, all of these assets need maintaining; leaking air hoses can lead to high compressor duty cycles plus early failures, gasoline tanks can leak and theft can occur, and HVAC leaks can lead to a significant decline in performance and efficiency.

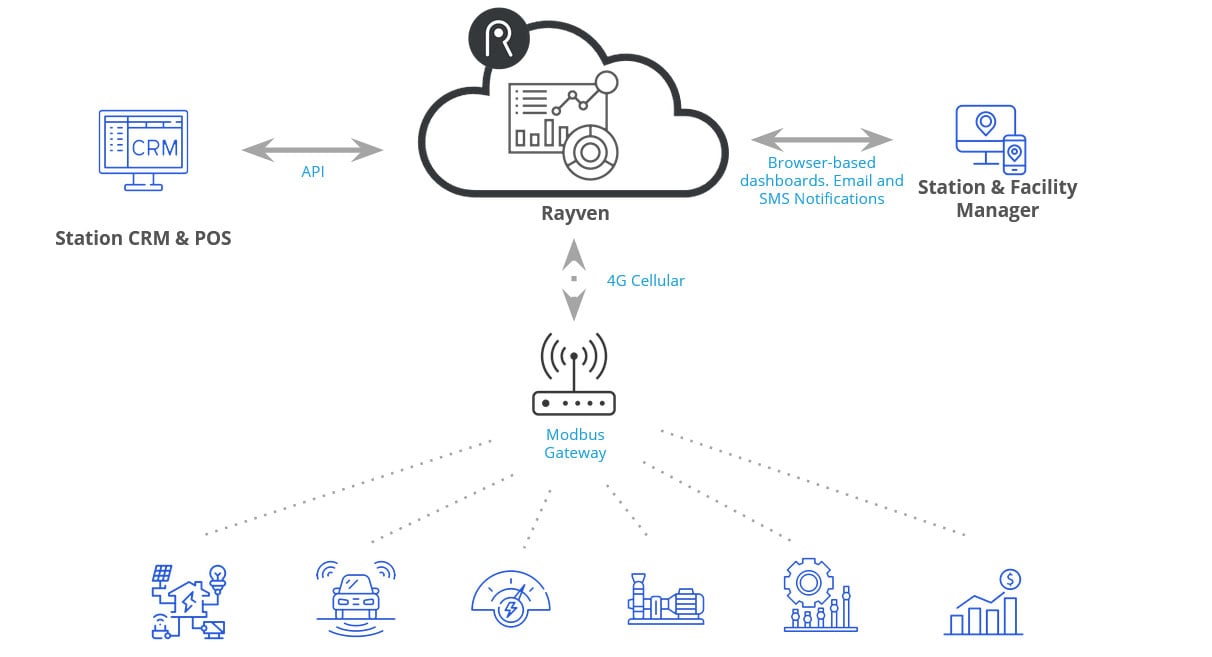

Remotely managing a chain of gas stations efficiently can be difficult, so how do you effectively minimise product loss, energy consumption and maintenance?