Fleet monitoring IoT solution: improving driving performance, safety + efficiency.

The problem

Fleet monitoring and management is difficult: how do you maximise the availability of your trucks, ensure that you meet customer schedules and protect the safety of your drivers and vehicles within a tight budget when all of your assets are normally out of view?

Ensuring the maximum utilisation of your assets is therefore key, but if you are carrying out maintenance on a scheduled basis, your vehicles might be spending more time off the roads than they need to. Worse still, you might not identify a problem until it is too late and a failure occurs.

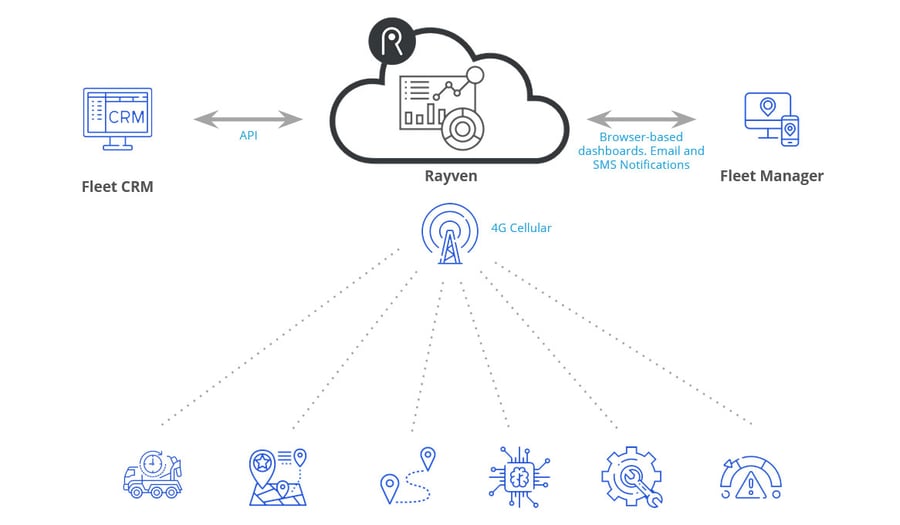

Rayven’s Fleet Monitoring IoT solution enabled one business to achieve it all - and more.