OPC integration.

Master OPC connectivity: deliver on the potential of a real-time datastack.

Unleash the full potential of your systems with Rayven's OPC integration. Achieve seamless data harmonisation for unparalleled operational insights and efficiency.

Integrate OPC data into your wider IT / OT ecosystem + future-proof your architecture, simply.

OPC integration is critical in creating effective applications as it ensures seamless and reliable communication with a wide range of devices. It provides standardised, real-time access to machine data, essential for monitoring, analysis, and automation, thereby enhancing operational efficiency, predictive maintenance, and overall system interoperability.

Our Rayven Platform excels in real-time data unification, analysis, and data push; enabling you to easily integrate an almost unlimited number of AWS S3 (and other) data sources and systems to create a real-time single source of truth and a robust, future-proofed modern architecture.

Rayven is dynamic, scalable, and easy-to-use; deliver improved unified data streams, future-proof your architecture, and create a completely interconnected technology ecosystem, simply: speak to us today to get started.

Drag-and-Drop Configuration.

Integrate any data source, in any format to create a real-time source of truth.

Data Verification + Alerts.

Automatically verify data validity in real-time and be alerted to issues.

Data In/Out + Interoperability.

Ingest all your data from anywhere and push it to any system.

Complete Data + Industry 4.0 Kit.

Apply machine learning, create automations + build custom applications, simply.

Secure Data, Everywhere.

Built with enterprise security and encryption baked-in at all-points.

Automatic

Back-up + DR.

Get reliable, anytime access to your data, always from anywhere.

How our OPC integration works.

The Rayven OPC node uses the OPC UA protocol to request data from remote PLCs via an OPC UA server. The OPC node will request updates for designated signal fields at the specified rate and add returned values to the JSON object under a new field name.

OPC Unified Architecture (OPC UA) is a cross-platform, open-source, IEC62541 standard for data exchange. It replaces OPC Data Access (OPC DA), which only communicates real-time data (not historical data, alarms, or events).

Connecting OPC data sources to Rayven is incredibly simple and only involves a few short steps to ensure a seamless, secure integration.

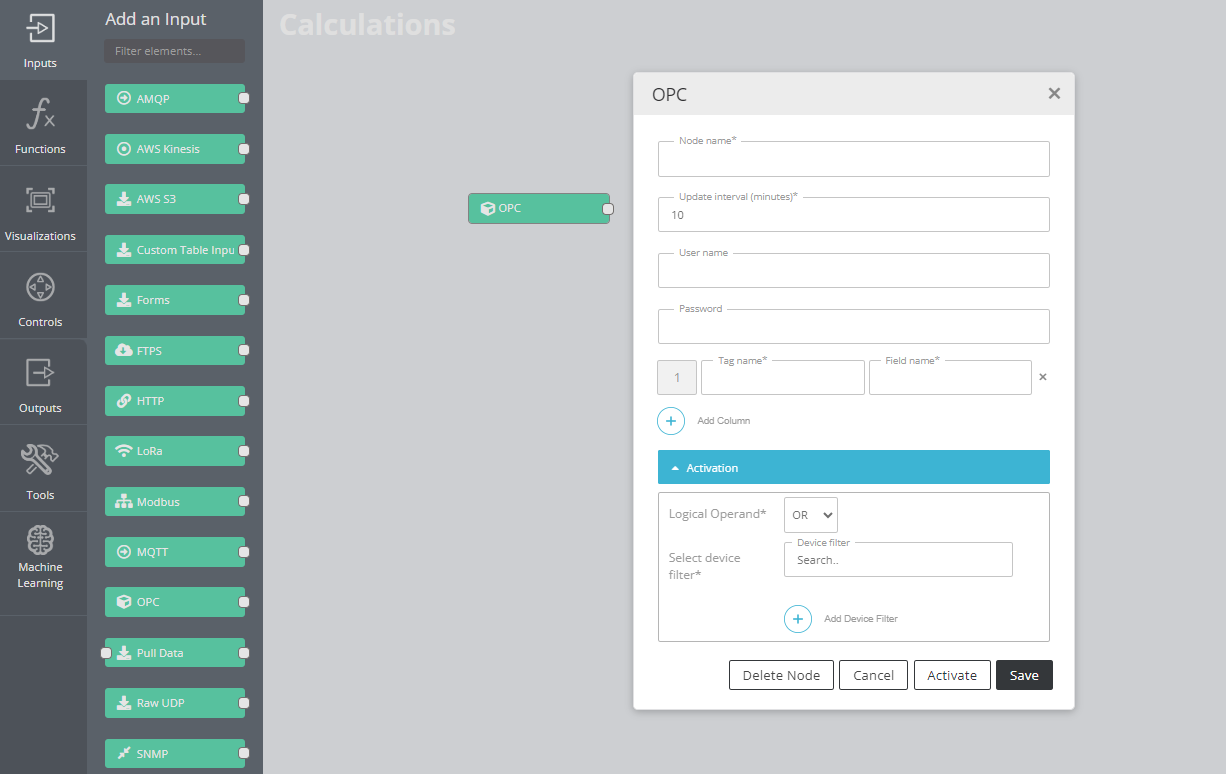

1. Select the OPC Node.

Drag-and-drop it onto the Rayven workspace from the nodes list and name it.

2. Configure.

- Define the interval between requests to the designated IP address using the 'Update Rate' field.

- (Optional) Choose whether to enter a username. If setting a username, it needs to be the same as the one in the OPC server.

- (Optional) Choose whether to set a password. If used, this needs to match the password set in the OPC server.

- Enter the signal name as received from the OPC server. You must identify at least one OPC signal.

- Add Value button. The OPC node will make requests at the specified update rate for designated signal fields.

- Add a value signifier for transferred PLC data under 'Field Name'.

- Select the appropriate Device Filter.

3. Activate.

Click 'Activate' and then 'Save'.

4. Security (optional).

Set-up SSL/TLS encryption as required.

Features + benefits of Rayven's OPC integration.

Easy-to-use + fast-to-deploy, our platform enables you to build multiple, custom applications and automations using your OPC data, simply.

Cross-Platform Compatibility.

Rayven enables communication between different platforms, devices and software in any format.

Efficient Real-Time Data Transmission.

Rayven matches OPC's standardised, reliable transmission; supporting real-time data analysis + ETL.

Integrated,

All-in-One + Scalable.

Rayven is built to scale and can support a large number of integrations and high-volume data throughput.

Customisation + Flexibility.

Rayven's platform can be customised to fit specific business needs using OPC (or any other data source/format).

Advanced Security for Data.

Rayven has end-to-end enterprise security built-in.

Operational Efficiency + Cost-Effectiveness.

Create powerful applications without extensive custom development.

Ease-of-Use + Low-Code Setup.

Workflow Modeller: Create custom business logic and integrate assets or existing applications, simply. The drag-and-drop interface simplifies the process of creating rules, connecting systems, and putting in place sophisticated processes without having to write any code.

Automations: Users can easily create automations and control machinery through a straightforward drag-and-drop interface. This feature simplifies the process of data ingestion and allows for rapid development and deployment of automated applications.

Rapid Applications Development: Design, deploy, and scale automations quickly. Integrate any system, data feed, and component; streamlining the process of creating comprehensive, end-to-end applications.

Machine Learning + AI Integration: Rayven's platform has inbuilt machine learning and AI capabilities. Users can deploy trained algorithms into their solutions using drag-and-drop, adding advanced Industry 4.0 capabilities to applications.

Interactive Controls: The platform allows for the creation of interactive controls and the implementation of real-time push instructions. This feature enables users to automate device decisions and enhance the efficiency and responsiveness of applications.

Reduced infrastructure + maintenance: Rayven reduces the overheads and complexity associated with running and maintaining IT/OT infrastructure, especially when it comes scalability, interoperability and performance optimisation.

Rayven has free + low-cost options, making it affordable for every business.

Our platform is ultra-interoperable middleware, as well as a complete toolkit for creating world-leading applications.

Rayven's platform enables you to combine + analyse data from anywhere + in real-time - no matter the format - and comes with ready-to-go connectors for 20+ data protocols, including:

Level 1 Data: Manual entry of data via custom forms built within our solutions.

Level 2 Data: Bespoke spreadsheet ingestion via FTP or manual uploads.

Level 3 Data: Integration of real-time data from IT / OT systems + corporate systems.

Level 4 Data: Real-time integration with in-field systems + sensors.