Machine Learning Studio

Use your real-time data to find insights, predict the future + self-optimise.

Use our platform's inbuilt Machine Learning Studio to test machine learning algorithms, train them, visually compare performance + then add them into your workflows, simply, to add accurate forecasts and predictive insights to your applications.

Rayven's easy-to-use Machine Learning Studio enables you to create, test + train algorithms; and then add them to applications to deliver Predictive Analytics, simply.

Rayven's Machine Learning capabilities are a built-in feature of our integrated data, AI + IoT platform + comes as-standard, enabling you to turn your real-time data into forecasts and deliver predictive insights in the moment.

The predictive power contained within our platform enables you to build applications that empower users (and machines) to reduce risk, shrink costs, uncover optimisations, and self-optimise operations, simply.

Import Python or create your own algorithms

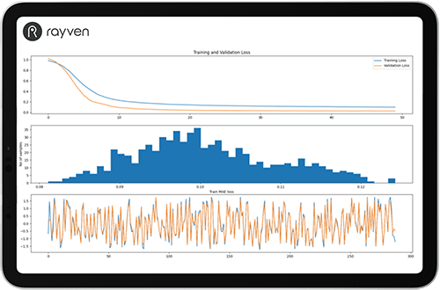

Easily train, test + compare models visually

Deploy + use on real-time data, in 1-click

Explore inputs, + model scenarios, fast

Export results + alter processes anywhere

Create self-optimising loops, simply

Rayven makes it easy to leverage the power of predictive analytics to minimise real-time risks + maximise performance.

Dig deeper into your data using our platform's easy-to-use, inbuilt Machine Learning Studio.

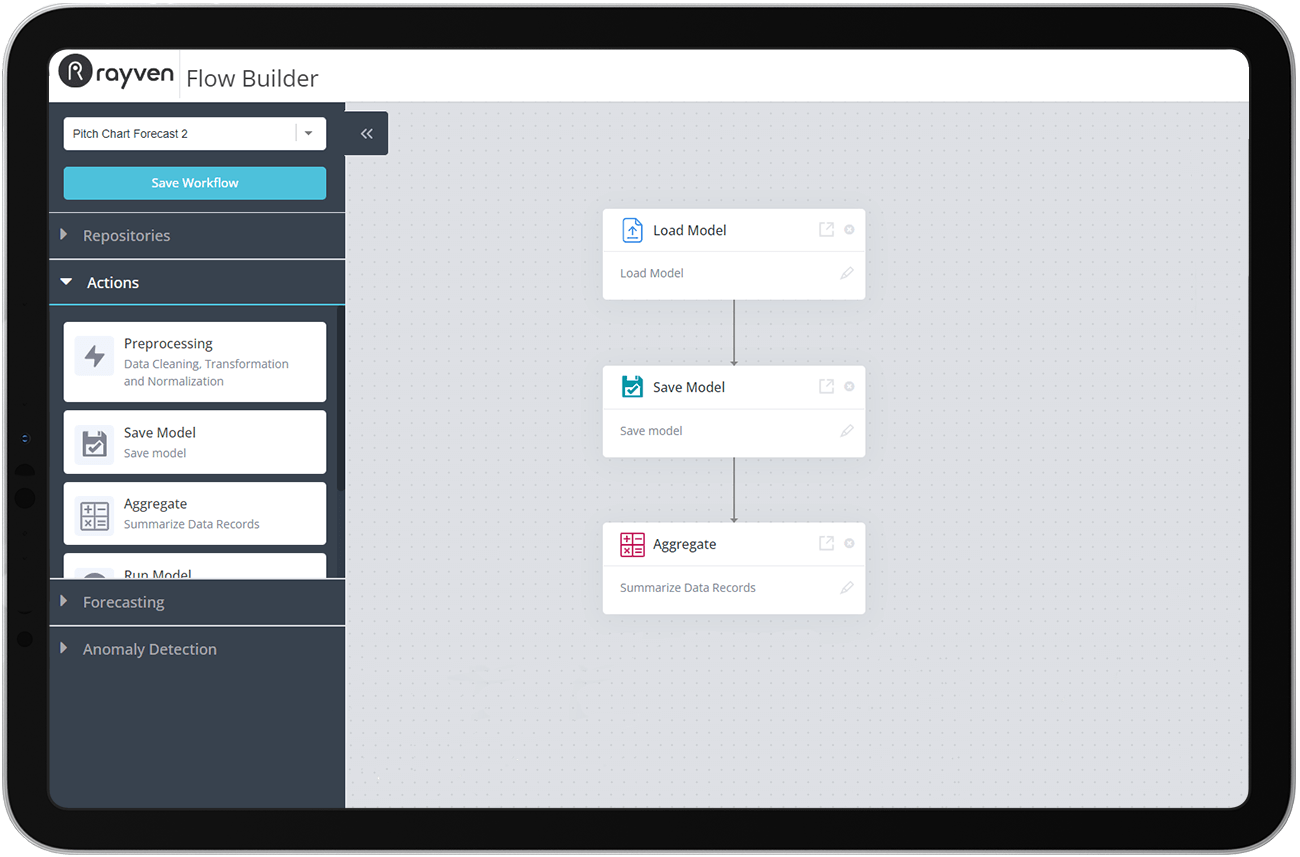

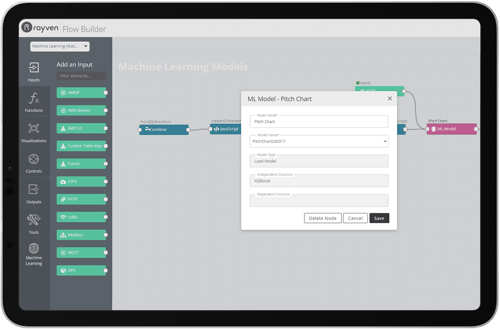

Our platform's Machine Learning Studio enables you to not only create, train and deploy any Python-based algorithm into your custom applications using our Workflow Builder, but also to model and test them against each other to see which works best - all via an easy-to-use drag-and-drop interface.

Our Machine Learning Studio comes pre-built into our integrated data, AI + IoT platform and enables non-developers and Data Scientists alike to dig deeper into their data and add accurate predictive analytics in their custom applications, delivering maximum value to their end users and customers.

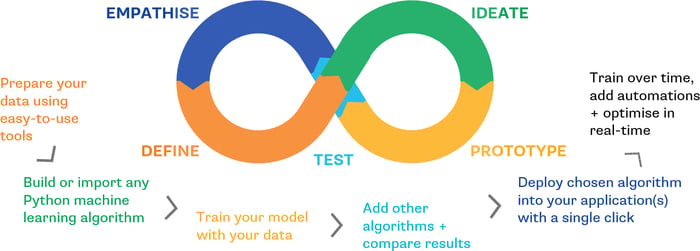

1: Prepare your data.

Select training data from your wider solution and apply ready-to-go filters and normalisers that are natively available within our Machine Learning Studio.

2: Create, import + train.

Anyone can use our Machine Learning Studio's drag-and-drop interface to create an algorithm from scratch or import another Python-based model, before running iterative training.

3: Deploy + predict.

Deploy your trained model to streaming data in the Workflow Builder with a single click and visualise the results in your dashboard for real-time future insights.

Bring your own model: Rayven supports any Python-based predictive analytics model, including:

Need help building a Machine Learning model? We can help you to deploy predictive analytics in your applications in days, not months.

Getting your Machine Learning model looking at past data and suggesting optimisations is one thing, but training it to tell you what’s about to happen in real-time based on how you’re operating at that moment can be transformative.

Getting your Machine Learning model looking at past data and suggesting optimisations is one thing, but training it to tell you what’s about to happen in real-time based on how you’re operating at that moment can be transformative.

Rayven will help you to:

- Define your goals, identify the data that affects it and where it's stored and how to get to it in real-time.

- We combine and integrate existing, historical, training, human-entered, static and real-time data flow to build a repository.

- Create data visualizations + dashboards to support pre-processing and simulation.

- Pre-process your data. Conduct data validation, cleansing, sifting, decomposition, filtering, ordering, spectral decompression to determine what is relevant and establish parameters for the future.

- We build the data model that your algorithm will be based on or import yours.

- Build the algorithm based on your desired outcomes.

- Deploy the model in our simulator anad run it with your data to train your algorithm and check it's correct.

- We deploy it into your solution, ensuring it’s working.

- Over time and with larger data repositories, we can fine-tune your model, trial new ones, or add additional use cases.

Build your own algorithms, simply.

Train, test, compare, deploy + scale use, rapidly.

Use on real-time data to deliver instant insights.

Create self-optimising operations faster.

Every feature you need + others you’ll want tomorrow in one platform.

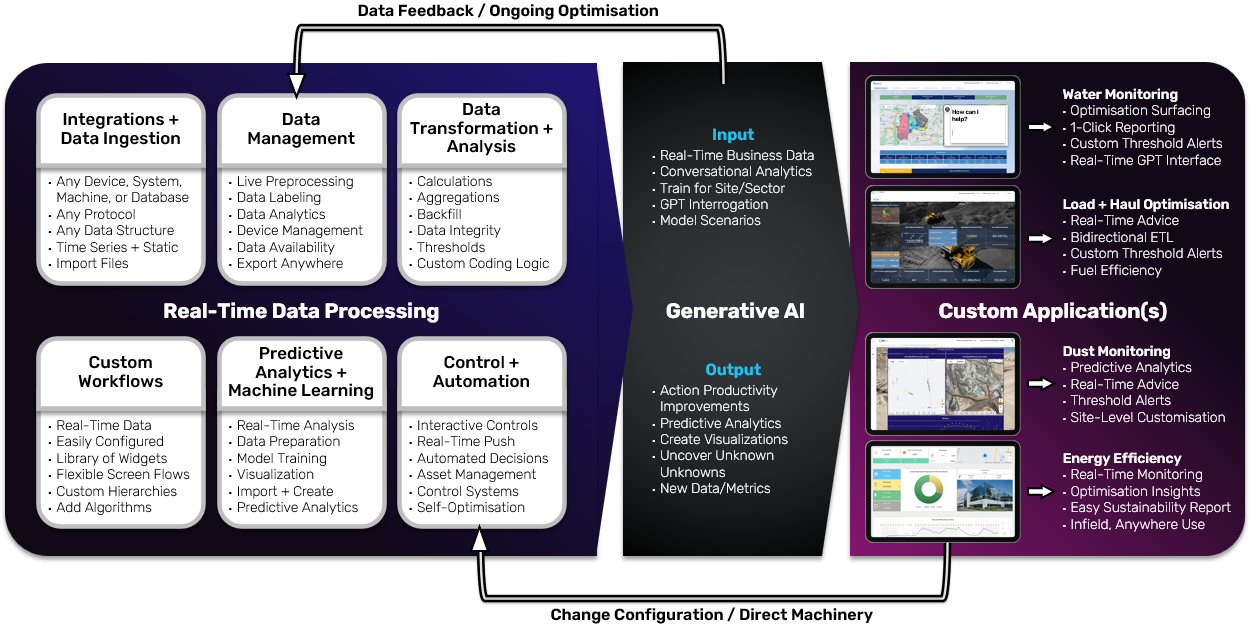

Easy-to-use, fast-to-deploy + delivering extreme capabilities; Rayven gives you an integration (iPaaS), ETL, Data, Workflow, Machine Learning, IoT, Analytics, AI + App Development platform in-one.

Pay only for what you do + get a platform that will grow with your business and needs - get started today, simply.

Explore some of our platform's other features:

Generative AI

Our platform's inbuilt Generative AI capabilities enable you to use custom LLMs, build RAGs + make conversational analytics available for users to explore your real-time data and optimise operations, everywhere.

Develop models that are tailored for your businesses and its precise needs, put in place custom safeguards + limits, and make Generative AI available across your business, simply.

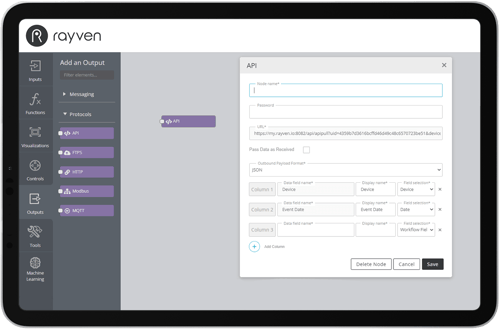

Integration + Data Ingestion.

Rayven is ultra-interoperable middleware that's can connect to any device, database, system, SaaS, machine, third-party data feed - anything - both fast and simply.

It does this using a unique toolkit of scripts, integration nodes and out-of-the-box connectors that can connect at a deeper, protocol level. The result is you can ingest data in any format, structure, static or time-series, via file import, and more.

Data Transformation + Real-Time Analysis.

Rayven makes it simple to clean, normalise + prepare all of your data for analysis - in real-time.

Beyond pre-processing, we make it easy transform you data and align it for the multiple purposes you may have for it; whether that's for use in Machine Learning and LLMs, executing machine control commands, pushing data elsewhere - anything.

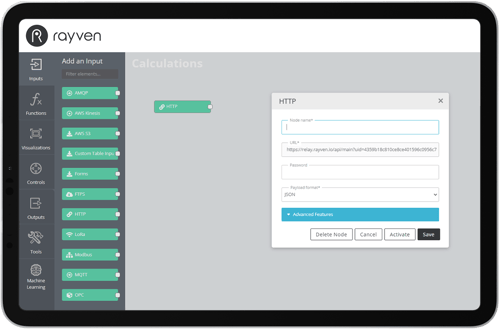

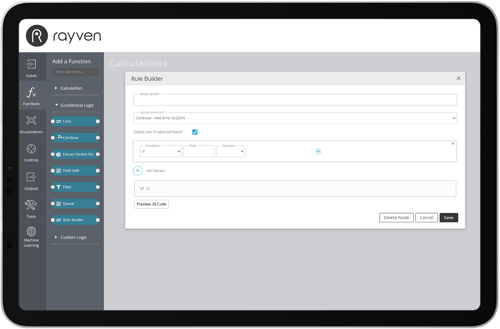

Custom Workflows.

Our Workflow Builder is the drag-and-drop interface that enables you to easily create rules, connect systems, trigger alerts, automate processes + much, much more.

Creating workflows is incredibly simple and consists of dragging onto the builder different types of 'nodes' and connecting them in different ways to deliver action based on your goals.

Control + Automation.

Our platform enables you to orchestrate processes and execute commands within and outside the platform.

Rayven enables you to create rules, control machines + put in place sophisticated automations that put in place self-optimising operations based on real-time, real-world performance - all without writing a line of code.